Guarantee for a perfect match

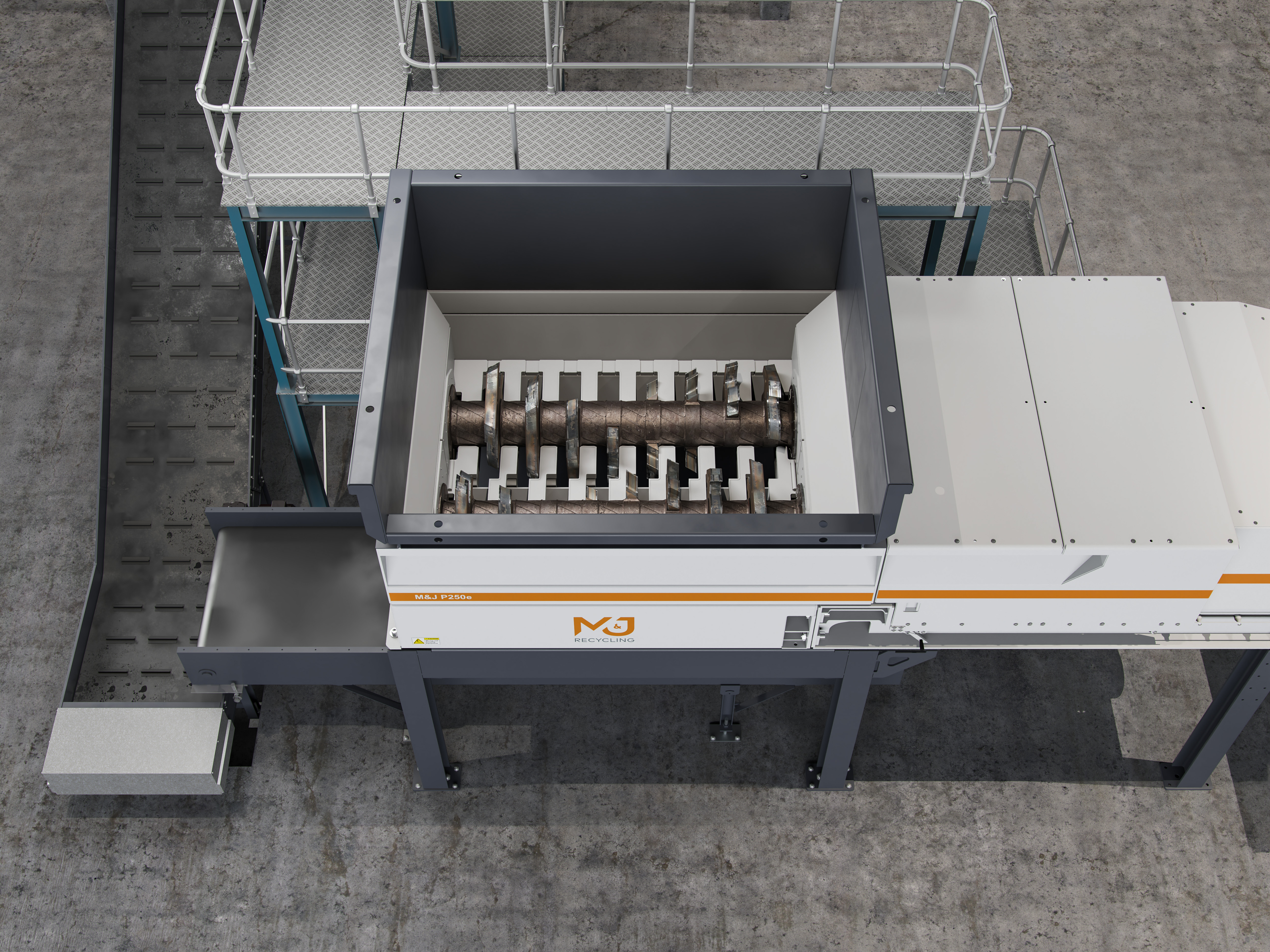

M&J P250e is a complete series of superior pre-shredders with e-drive, catering to all needs. Heavy-duty applications or lighter waste streams? There's an M&J P250e for every single requirement. And it offers up to 50% less energy consumption.

The M&J P250e comes in four configurations, all of which can be fitted with 6, 8, 9, 10 or 12 knives per shaft. This means that we can assemble a machine that matches your needs more precisely than any other pre-shredder on the market. We can also quickly adapt your machine to new waste streams if you need it in the future.

It’s close to being a revolution!

M&J P250e

220hd

M&J P250e

220hs

M&J P250e

320hd

M&J P250e

320hs

Best choice for LIGHT to MEDIUM DUTY applications.

Best choice for MEDIUM DUTY applications.

Best choice for MEDIUM to HEAVY DUTY applications and SMALL GRAIN SIZE.

Best choice for HEAVY DUTY applications and SMALL GRAIN SIZE.

You only pay for what you need

Enjoy a smooth operation with optimal utilization of the M&J P250e every single day. You won’t experience a lack of power to shred waste, and you don’t pay for power you don't need.

There are several advantages to having the shredder tailored to your specific needs.

- You save significant amounts on energy for production

- You get a machine that wears down slowly because it is designed for the specific task

- You avoid frustrating breakdowns because the shredder always meets the production requirements.

M&J P250e means operating expenses (OPEX) in a class of its own!

Future proof engineering

With M&J P250e, you get a future-proof pre-shredder that always matches your needs!

- Better welding access for hard facing on the cutting table

- Targeted replacement of only the parts that are worn

- No need to disconnect power supply to the drive

- Nuts and bolts make it easy to disconnect the drive module

- In fact, you can change the entire cutting module in less than 1 hour!

The modular design also makes it easy to adapt the machine to future needs. You can replace the drive unit and/or change the cutting module, if the composition of your waste material changes significantly in the future.

Homogeneous end product in the desired size

An extremely aggressive knife design ensures outstanding performance when dealing with mixed and challenging materials. It is also possible to achieve a grain size of 90% <100 mm with 12 knives per shaft.

Get ready for pure electrical advantages.

M&J values your visit to our website and your interest in our products. We want you to feel secure visiting our site, and we assure you that your personal information is safe with us. Read more about our privacy policy.